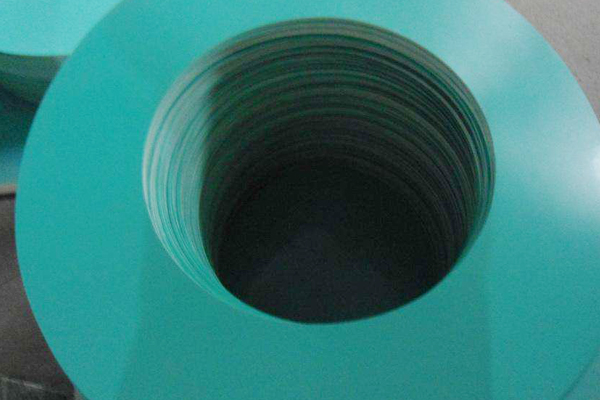

Steel coil Protection boards combine excellent plasticity with impact resistance, low-temperature resistance, wear resistance, chemical resistance, self-lubrication, and strong shock-energy absorption.

Therefore, they protect steel coils from impact, water, and compression damage during storage and transportation.

Moreover, the smooth and flat surface offers high compressive strength, heat resistance, corrosion resistance, aging resistance, impact resistance, low-temperature resistance, and wear resistance.

As a result, these boards serve as ideal new packaging materials for stainless steel coils, hot-rolled coils, cold-rolled coils, and galvanized steel coils.

Specific Packaging Steps for Steel Coil Protection Board

- First, lift the steel coil to the packaging position and install the paper inner liner.

- Next, straighten the VCI paper and plastic film, fold the edges, and press them 100–200 mm into the coil core evenly.

- Then, fix the VCI paper and plastic film onto the paper liner with 300 mm tape, forming about 20 uniform, tightly pressed folds.

- After that, install the PVC antistatic protective film outside the VCI paper to provide waterproof protection.

- Subsequently, install paper or plastic side protectors and secure them with equal-length tape at intervals of about 300 mm.

- Then, install the plastic outer circumferential protector, positioning the joint at 3 or 9 o’clock with the opening facing downward.

- Seal the overlap with cloth tape to prevent water ingress and avoid impact damage during transportation.

- Next, install the plastic inner wrapping board in a cylindrical form, placing the overlap centerline at 12 o’clock.

- Seal the joint firmly with cloth tape to ensure secure wrapping.

- Afterward, install the outer steel corner protectors.

- Then, install the plastic side protectors, ensuring welded seams face downward to prevent rainwater penetration during handling or transport.

- Next, install the inner steel corner protectors.

- Apply circumferential strapping, tighten two straps around the outer corner protectors, and place buckles near the 12 o’clock position.

- During tightening, tap raised corner protectors flat with a rubber hammer, and apply the middle strap after completing longitudinal strapping.

- Then, apply longitudinal strapping evenly with four straps around the coil core, aligning buckles on the same circumferential side.

- Ensure one strap presses the joint between inner and outer protectors, and tap corner areas with a rubber hammer while tightening.

- Finally, packaging workers attach one label each to the inner circumferential protector and both side protectors.

Conclusion

Using steel coil Protection boards ensures coils remain secure, dry, undeformed, and undamaged during normal transportation and storage.

Therefore, steel coil Protection boards mainly suit the packaging needs of various steel coils in the metallurgical industry.